The hum of new machinery fills production workshops, signaling a quiet transformation underway in the new energy, food & beverage, and semiconductor sectors—an industry-wide upgrade focusing on compressed air quality and energy efficiency.

Amidst a resurgence in manufacturing investment, the compressor market, often termed the "heart of industry," is witnessing structural opportunities.

As downstream applications undergo technological iteration and standards rise, the market space for generic, low-standard compressor products is shrinking. Conversely, demand for high-end, specialized compressor systems that meet the stringent requirements of specific industries continues to climb.

The benefits of the market recovery are not evenly distributed; demand is rapidly concentrating in three "bellwether" sectors: new energy lithium battery manufacturing, food & beverage processing, and semiconductor & electronics manufacturing. For these industries, the requirement for compressed air systems has evolved from a question of "availability" to one of "quality and reliability."

Industry Trends

Against the backdrop of a manufacturing recovery, the compressor market is undergoing profound changes. Traditional demand growth remains sluggish, while emerging high-end manufacturing sectors demonstrate strong purchasing intent.

The rapid development of the new energy, food & beverage, and semiconductor industries is reshaping the demand structure of the compressor market. These sectors require not only the basic air supply function of compressors but also impose near-stringent standards for air quality, energy efficiency, and system reliability.

This shift is pushing compressor suppliers to transform from general equipment manufacturers to industry-specific solution experts. Market growth is transitioning from "quantity" expansion to "quality" enhancement, manifesting in significantly increased demand for high-value-added, technologically advanced compressor products and systems.

New Energy Sector: Compression Technology Behind Zero-Risk Production

Lithium battery manufacturing has become a representative scenario for high-end compressor applications. In critical processes such as drying, electrolyte filling, and sealing, compressed air comes into direct contact with electrode materials and electrolytes. Any contamination can lead to reduced battery performance or even safety hazards.

The core requirements for compressed air systems in this field can be summarized as absolute cleanliness and absolute stability. Specific metrics include an oil content below 0.01 mg/m³, a dew point temperature of -40°C or lower, and solid particulate filtration down to the 0.01 μm level.

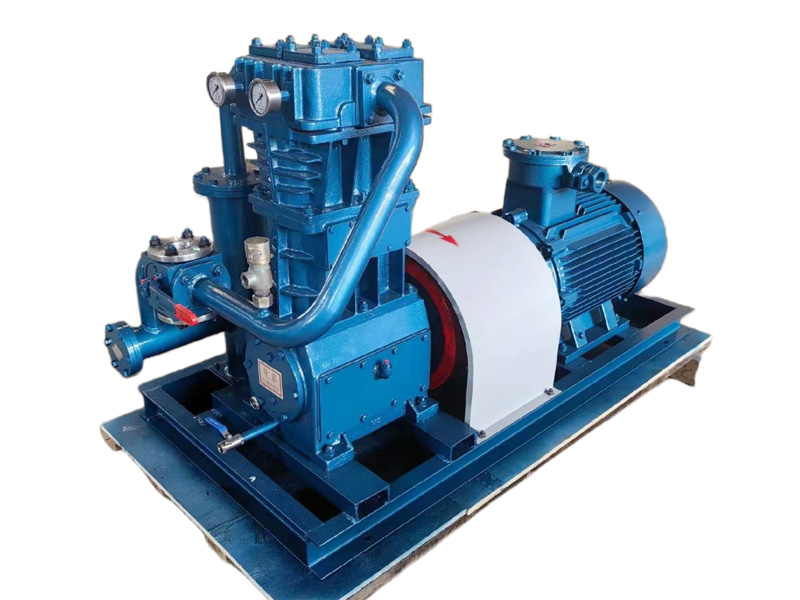

For compressor sales targeting the new energy sector, the technical focus should be on integrated solutions combining oil-free screw technology, efficient drying systems, and multi-stage precision filtration. Oil-free screw compressors, eliminating oil contamination risk at the source, have become the preferred choice for most lithium battery manufacturers.

More important than merely providing equipment is a sales strategy centered on "ensuring zero risk in production safety." This necessitates providing complete validation documentation, including third-party test reports, material compatibility certifications, and case studies of stable operation at similar client sites.

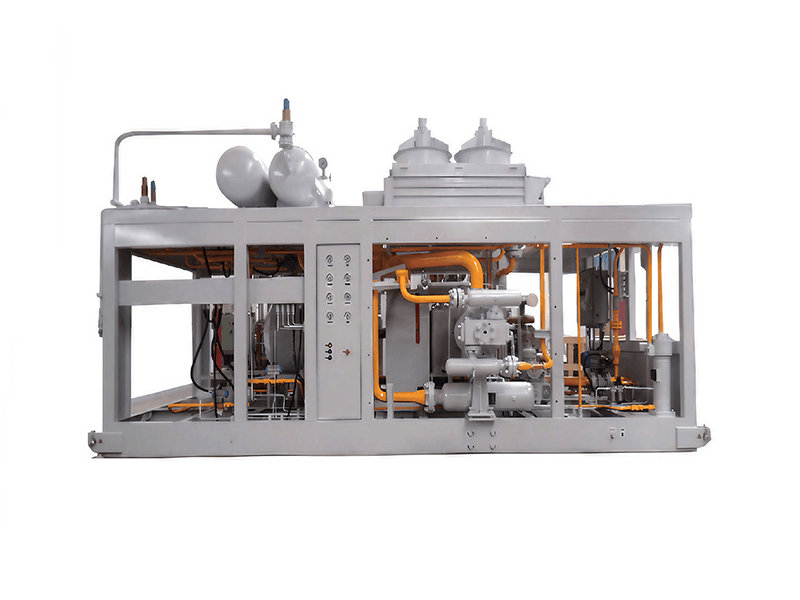

Air compressor system configurations in lithium battery workshops often require multi-level safeguard designs, including backup units and dual-loop air supply, ensuring that no single point of failure disrupts continuous production.

Food & Beverage Industry: The Dual Pursuit of Safety and Efficiency

Driven by heightened consumer focus on food safety and stricter industry regulations, requirements for compressor systems in the food & beverage industry have upgraded from "functional" to "compliant with food safety standards."

This industry pays particular attention to food-grade certifications for equipment materials, the non-toxic and harmless nature of lubricants, and hygienic, easy-to-clean equipment design. Any potential risk of product contamination must be eliminated at the source.

Compressor applications in the food & beverage sector are diverse, including bottle/blow molding, material conveying, packaging machinery power, and fermentation aeration. Different scenarios have varying requirements for compressed air quality, necessitating tailored solutions.

Variable Frequency Drive (VFD) technology holds exceptional value in this industry. Food & beverage production often exhibits significant peak-and-valley air demand. VFD compressors can automatically adjust output based on actual consumption, avoiding unnecessary energy waste and directly reducing client operational costs.

Hygienic design is equally crucial, encompassing features like stainless-steel enclosures, crevice-free surfaces, and food-grade coatings. The sales process should highlight the ease of cleaning and how the equipment facilitates compliance with various food safety audits.

Semiconductor Industry: A Systemic Contest Beyond Standalone Machines

Semiconductor manufacturing represents the most demanding field for compressed air quality, serving as the ultimate "proving ground" for compressor technology. In processes like wafer fabrication, chip packaging, and testing, minuscule contaminants can lead to significant yield losses.

This industry commonly requires compliance with ISO 8573-1 Class 0 oil-free certification, with some processes demanding even stricter industry-specific standards. This necessitates comprehensive pollution control throughout the entire compressed air system, from source to point-of-use.

For semiconductor clients, compressor suppliers must complete a transition from equipment vendors to air system solution providers. No single piece of equipment, however excellent, can meet the extreme demands for system stability in semiconductor manufacturing.

Successful compressor solutions for the semiconductor industry must encompass total system integration capabilities: from the oil-free main unit to adsorbent dryers, precision filters, piping systems, and monitoring controls to emergency backup systems. Every component must be seamlessly integrated and meet a uniformly high standard.

System reliability is the core concern for semiconductor customers. The sales process should emphasize presenting product MTBF (Mean Time Between Failures) data, case studies of system redundancy design, and a rapid-response service network, providing concrete evidence of the ability to support clients' 7x24 continuous production needs.

As semiconductor chip processes advance towards 3-nanometer and smaller scales, air purification standards have evolved from cubic-meter measurements to precise particle counts per liter of air. Behind this production model, where "every liter of air holds immense value," lies a vast and precise engineering feat comprised of oil-free compressors and multi-stage drying and filtration systems.

On food & beverage production lines, a compressor compliant with HACCP certification must meet standards for interior surface smoothness and oil circuit sealing that rival those of food-contact processing equipment itself.

In new energy battery plants, Class 0 oil-free certification has become a baseline requirement rather than a mere advantage for compressor procurement.

The common thread among these three sectors is that compressed air has transformed from a simple power source into a core production element. Its quality is directly linked to product quality, production safety, and corporate competitiveness. Technical solutions capable of delivering compressed air "as pure as the product itself" are playing a pivotal role in this manufacturing upgrade.